Loadrite

Working closely with the team at Loadrite, I led the design of an intuitive interface for heavy-machinery operators working in multi-hazard, time-pressured environments. The new interface aims to reduce waste on-site, improve productivity and make learning the system easier for new operators.

Role

Responsibilities

Role

Responsibilities

Design Lead

Research

Conceptual design

Prototyping

Conceptual design

Prototyping

UX and UI design

Usability testing

Championing HCD

Usability testing

Championing HCD

The Opportunity

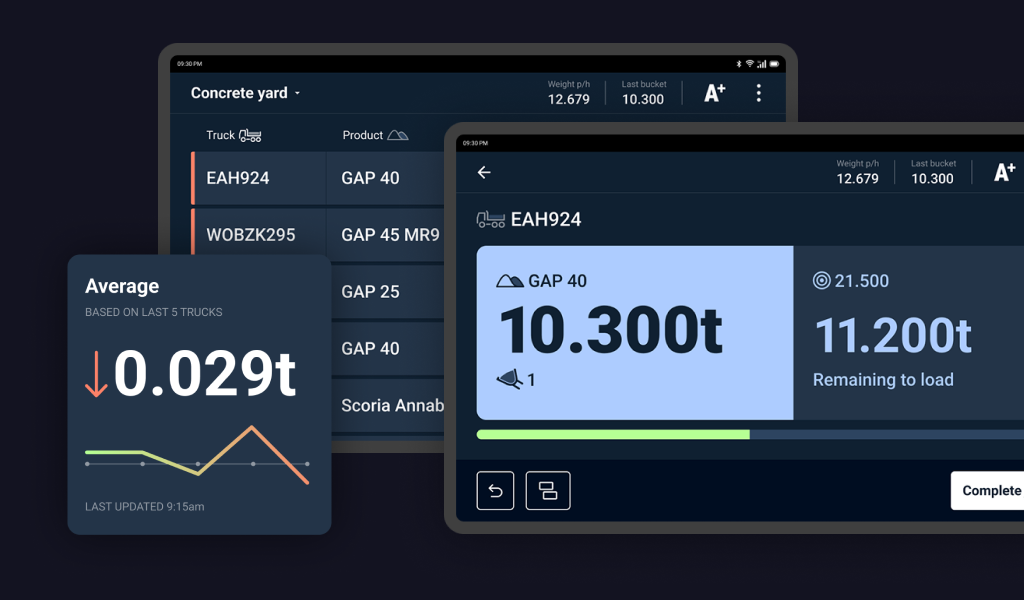

Loadrite’s core business is producing physical scales and software for wheel loaders, excavators and other heavy machinery. The physical scales measure the weight of the material collected which is then displayed to operators via an in-cab interface. This process helps operators reduce waste by giving them accurate readings of the amount of material they have picked up, as well as the amount they still need to load. It also improves efficiency and ensures that the trucks they are filling do not exceed their weight limits and become a danger to other road users when they are transporting materials between construction sites.Loadrite were looking to move away from their outdated software and hardware, and onto an Android-based tablet system, a change that created an opportunity to design an expereince that is easier to learn and use long-term.

The Approach

Although what the wheel loader operators are doing seems simple - picking material up and putting it in a truck - in order to do it effectively, operators are trained on very complex machines. Our designs needed to take into account physical constraints, like cramped cab environments, wet or muddy hands, and an ageing workforce, as well as reduce unnecessary distractions to support working in a stressful operating environment.We carried out initial customer research on our concept designs in a real world context of quarries across Tāmaki Makaurau, and remotely with Loadrite’s international customers. A key finding during the research phase was that on some sites operators are moving between different machines and tasks, so needed to re-learn the original scales interface when they came back to the wheel loaders. This leads to more experienced operators spending time re-teaching people how to use the interface, taking tghem away from the job at hand.

Working closely with subject matter experts to gain a deep understanding of our users' needs we progressed our concepts into detailed designs, and tested these with operators on-site and internationally. In these detailed designs we simplified workflows to make it easy for both new and experienced users. We also grouped content and made actions contextual to make things easier to find. Using colour helped communicate and reinforce information, so operators could be confident about what they needed to do next.

The Outcome

After a pilot across several quarries and construction sites, the system is now being rolled out throughout Aotearoa and internationally.Key results:

- Reduced time for operators to learn how to use the scales due to improved usability.

- Made the experience of using the app easier for operators in a complex, multi-hazard environment.

- Supported Loadrite to meet their goals of reducing waste and meeting legal obligations.

- An extensible design framework that can be rolled out to other types of machines in the future.

- Demonstrating the value of human-centred design for digital products, a new approach for Loadrite.

︎ Previous Next ︎